1. Introduction to ASPICE

1.1 What is Automotive SPICE?

Automotive SPICE (ASPICE) is a process assessment and improvement framework specifically tailored for the automotive industry. It is designed to evaluate and enhance the software and systems development processes used by automotive manufacturers and suppliers. ASPICE defines best practices, process areas, and capability levels that help organizations deliver high-quality, reliable, and safe automotive products.

1.2 Why is it Important in the Automotive Industry?

Modern vehicles are highly dependent on software for critical functions such as safety, navigation, and driver assistance. Defective software can lead to costly recalls, safety risks, or regulatory issues. ASPICE:

- Ensures systematic, repeatable development processes.

- Helps meet stringent OEM requirements (e.g., Volkswagen, BMW often mandate ASPICE compliance).

- Reduces defects, increases reliability, and improves safety.

- Supports compliance with other industry standards like ISO 26262 (functional safety).

1.3 How is it Different from General SPICE or CMMI?

- SPICE (ISO/IEC 15504) is a general-purpose process assessment model.

- CMMI is another process maturity framework, broader in scope.

- ASPICE adapts SPICE specifically for automotive needs, adding process areas and requirements focused on automotive systems, including alignment with safety and OEM-specific requirements.

2. History and Evolution

2.1 Origins and Development

- SPICE (Software Process Improvement and Capability dEtermination) originated as ISO/IEC 15504, providing a universal framework for process improvement.

- Automotive leaders recognized the need for a domain-specific model, leading to Automotive SPICE, developed by the Automotive Special Interest Group (SIG) and the German Association of the Automotive Industry (VDA).

2.2 Relationship with ISO/IEC 15504

- ASPICE is based on ISO/IEC 15504 (now replaced by ISO/IEC 330xx), but customized for automotive system/software development.

- Maintains the core process assessment principles but tailors process areas, outcomes, and assessment criteria.

2.3 Key Milestones and Adoption in the Industry

| Year | Milestone |

|---|---|

| 2005 | First release of Automotive SPICE 1.0 |

| 2007 | OEMs begin to require ASPICE for suppliers |

| 2015 | Major update (v3.0) to align with modern development |

| 2020 | ASPICE becomes widely adopted, often mandated at Level 2/3 |

Major OEMs now require ASPICE assessments and certifications as a condition for business.

3. ASPICE Structure and Process Model

3.1 Overview of Process Groups

ASPICE is divided into three major process groups:

- Primary Lifecycle Processes

- Concerned with the core product engineering activities (acquisition, system, and software development).

- Supporting Lifecycle Processes

- Address quality, configuration, problem resolution, etc.

- Organizational Lifecycle Processes

- Focus on process management and improvement at the organizational level.

Table: Example Process Groups and Areas

| Process Group | Example Process Areas | Code |

|---|---|---|

| Primary | System Development | SYS.2 |

| Software Requirements Analysis | SWE.1 | |

| Software Design | SWE.2 | |

| Supporting | Configuration Management | SUP.8 |

| Quality Assurance | SUP.1 | |

| Organizational | Process Improvement | ORG.3 |

| Training | ORG.4 |

3.2 Explanation of Key Process Areas

SYS: System processes (e.g., SYS.2 – System Requirements Analysis)

SWE: Software engineering processes (e.g., SWE.3 – Software Detailed Design and Unit Construction)

SUP: Support processes (e.g., SUP.1 – Quality Assurance)

ORG: Organizational processes (e.g., ORG.3 – Process Improvement)

3.3 Capability Levels (Level 0 to Level 5) and What They Mean

| Level | Description | Characteristics |

|---|---|---|

| 0 | Incomplete | Process not implemented or fails to achieve purpose |

| 1 | Performed | Process achieves its purpose |

| 2 | Managed | Process is planned, monitored, and adjusted |

| 3 | Established | Process is defined and standardized |

| 4 | Predictable | Process is measured and controlled |

| 5 | Optimizing | Process is continuously improved |

Most OEMs require suppliers to reach Capability Level 2 or 3.

4. Detailed Walkthrough of Key Process Areas

Let’s focus on the most relevant process areas with practical details.

4.1 Requirements Engineering (SYS.2, SWE.1)

- Goals: Capture, analyze, and manage system and software requirements.

- Activities: Elicitation, documentation, validation, traceability.

- Inputs: Stakeholder needs, regulatory requirements, technical constraints.

- Outputs: System/software requirements specification, traceability matrix.

- Example Work Product:

- Requirements Specification Document (SysRS/SwRS)

- Requirements Traceability Matrix (RTM)

4.2 System Design (SYS.3)

- Goals: Define and document the system architecture/design.

- Activities: Develop system architecture, allocate requirements, interface definition.

- Inputs: Approved requirements, existing architecture standards.

- Outputs: System architecture documentation, interface specifications.

- Example Work Product:

- System Architecture Document

- Interface Control Document (ICD)

4.3 Software Development (SWE.2, SWE.3)

- Goals: Develop software architecture and implement code.

- Activities: High-level and detailed design, coding, unit testing.

- Inputs: Software requirements, system architecture.

- Outputs: Software architecture/design docs, source code, test results.

- Example Work Product:

- Software Design Specification (SDS)

- Source Code Repository

- Unit Test Reports

4.4 Testing (SYS.4, SWE.4, SWE.5, SWE.6)

- Goals: Verify and validate system/software against requirements.

- Activities: Develop test plans, design test cases, execute tests, report results.

- Inputs: Requirements, design docs, implementation artifacts.

- Outputs: Test plans, test cases, test reports.

- Example Work Product:

- System/Software Test Plan (STP)

- Test Case Specifications

- Test Summary Reports

4.5 Configuration Management (SUP.8)

- Goals: Control and manage changes to work products.

- Activities: Identify, control, status accounting, audit configurations.

- Inputs: Work products, change requests.

- Outputs: Configuration item list, change logs, audit reports.

- Example Work Product:

- Configuration Management Plan

- Change Request Records

4.6 Quality Assurance (SUP.1)

- Goals: Ensure that processes and products meet quality requirements.

- Activities: Plan quality assurance, conduct audits, report issues.

- Inputs: Project/process plans, standards, previous audit findings.

- Outputs: Audit reports, quality assurance records.

- Example Work Product:

- Quality Assurance Plan

- Audit Reports

5. Assessment and Capability Levels

5.1 How ASPICE Assessments are Conducted

- Assessments are conducted by qualified ASPICE assessors using interviews, document reviews, and process observations.

- Each process area is evaluated against defined base and generic practices.

5.2 What Assessors Look For

- Evidence that required activities are performed and work products are produced.

- Consistency, completeness, and traceability in documentation.

- Process adherence (are teams following defined processes?).

5.3 Practical Tips for Preparing for an ASPICE Assessment

- Maintain organized and up-to-date documentation.

- Ensure traceability from requirements through to testing.

- Conduct internal audits and gap analyses before external assessments.

- Train teams on ASPICE requirements and assessment expectations.

5.4 Example Scoring and Reporting

| Process Area | Capability Level Achieved |

|---|---|

| System Requirements | 3 |

| Software Development | 2 |

| Quality Assurance | 3 |

| Configuration Mgmt | 2 |

Results are reported by process area, showing achieved capability level and improvement recommendations.

6. Best Practices for Implementation

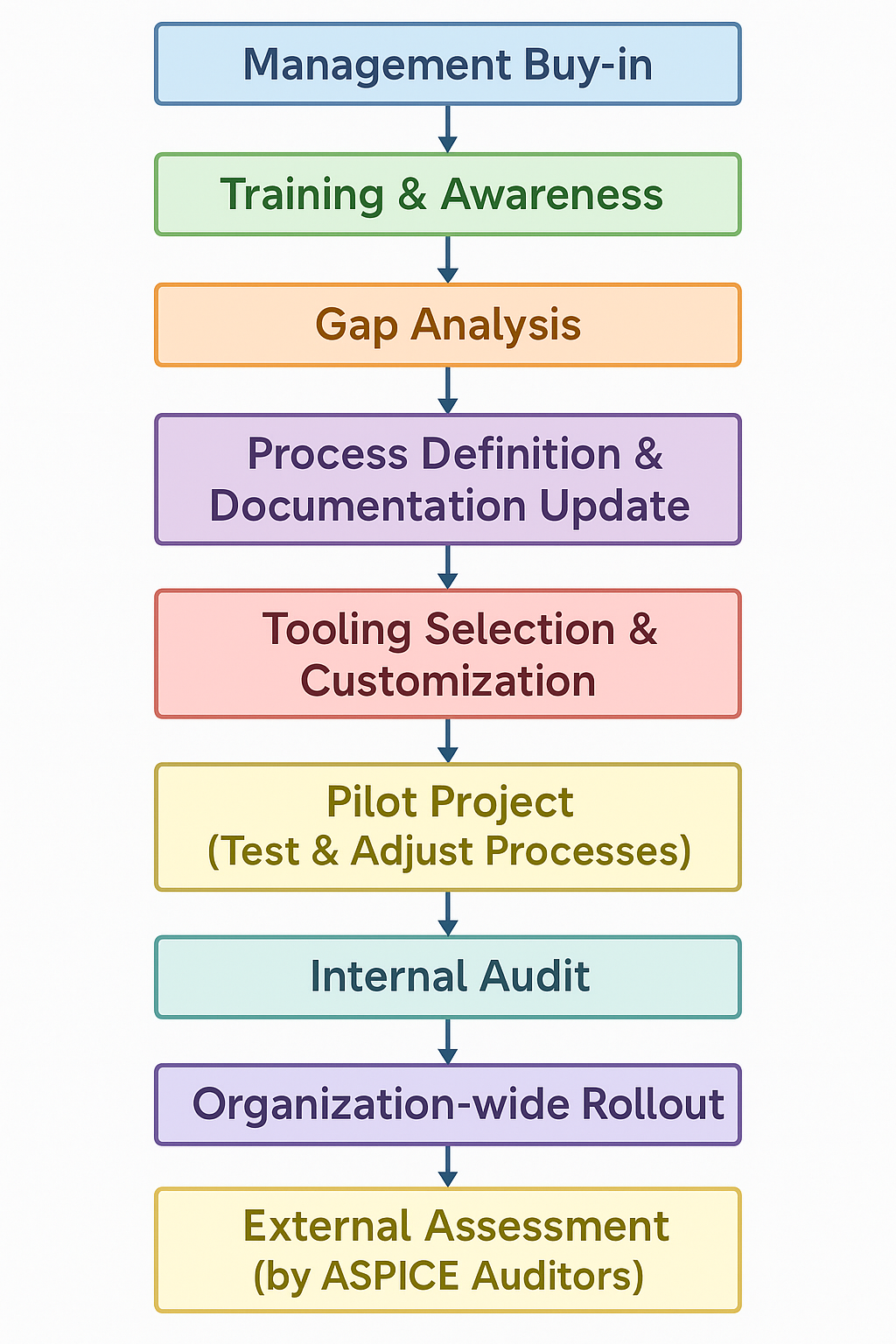

6.1 Steps to Implement ASPICE in a Real Automotive Project

- Secure Management Buy-In: Get leadership commitment and allocate resources.

- Gap Analysis: Assess current processes against ASPICE requirements.

- Process Definition: Define or update processes to align with ASPICE.

- Training: Educate teams on new/updated processes and ASPICE concepts.

- Tool Support: Implement supporting tools (requirements management, configuration management, etc.).

- Pilot Implementation: Roll out processes in a pilot project; adjust as needed.

- Internal Assessment: Conduct internal audits to identify gaps.

- Full Rollout: Implement improved processes across projects.

- Formal Assessment: Engage external assessors for ASPICE certification.

6.2 Common Pitfalls and How to Avoid Them

- Underestimating Documentation Needs: ASPICE requires thorough and consistent documentation.

- Insufficient Training: Teams need a clear understanding of ASPICE practices.

- Superficial Implementation: “Check-the-box” compliance without process improvement will fail audits and offer little value.

6.3 Case Studies or Practical Examples

- A Tier-1 supplier implemented ASPICE, reducing software defect rates by 40% and improving delivery predictability.

- A mid-size company failed initial ASPICE assessment due to poor traceability but succeeded after introducing a formal requirements management tool and process training.

7. ASPICE and Other Standards

7.1 Relationship with ISO 26262 (Functional Safety) and ISO/SAE 21434 (Cybersecurity)

- ISO 26262 focuses on safety; ASPICE focuses on process quality. Both require structured processes, documentation, and traceability.

- ISO/SAE 21434 addresses cybersecurity and aligns with ASPICE for process rigor in security-relevant development.

7.2 Integration with Agile, DevOps, and Other Process Models

- ASPICE is methodology-agnostic; it can be integrated with Agile or DevOps, as long as required artifacts and process evidence are produced.

- Agile sprints may align with ASPICE process areas by mapping sprint ceremonies to ASPICE activities (e.g., backlog refinement = requirements elicitation).

8. Tools and Resources

8.1 Recommended Tools for ASPICE Process Support

| Process Area | Tool Example |

|---|---|

| Requirements Mgmt | IBM DOORS, Jama, Polarion |

| Configuration Mgmt | Git, Subversion, ClearCase |

| Test Mgmt | HP ALM, Jira, TestRail |

| Quality Assurance | Jira, custom audit tools |

8.2 Templates, Checklists, and Further Reading

- Templates:

- Requirements Specification

- Traceability Matrix

- Test Plan and Report

- Configuration Management Plan

- Further Reading:

- automotivespice.com

- “Automotive SPICE in Practice” (Book)

- OEM-specific supplier handbooks

9. FAQs and Troubleshooting

Q: Is ASPICE only for software?

A: No, it also covers system engineering (hardware/software integration).

Q: How long does ASPICE implementation take?

A: For a mature organization, 6–18 months; longer if starting from scratch.

Q: Do we need expensive tools?

A: Not always, but robust tools for requirements, configuration, and testing help greatly.

Q: Can we be Agile and compliant with ASPICE?

A: Yes, but ensure all required artifacts and evidence are produced.

10. Conclusion

10.1 Summary of Key Takeaways

- ASPICE is critical for quality and compliance in automotive software/system development.

- Provides a structured framework for process improvement and assessment.

- Ensures repeatability, traceability, and compliance with OEM/safety requirements.

10.2 How to Get Started with ASPICE in Your Organization

- Begin with education and training for key teams.

- Conduct a gap analysis to assess current process maturity.

- Start small—pilot ASPICE-aligned processes in one project.

- Gradually expand, invest in tools, and seek formal assessment once ready.

Absolutely! Here are some clear, easy-to-understand diagrams to help visualize Automotive SPICE (ASPICE) concepts. These are suitable for your tutorial and can be recreated in PowerPoint, draw.io, Lucidchart, or other tools for presentations or documentation.

1. ASPICE Process Group Overview

+----------------------+ +-------------------------+ +-----------------------------+

| PRIMARY PROCESSES | | SUPPORTING PROCESSES | | ORGANIZATIONAL PROCESSES |

+----------------------+ +-------------------------+ +-----------------------------+

| - SYS.2: System Req. | | - SUP.1: QA | | - ORG.3: Proc. Improvement |

| - SYS.3: Sys Design | | - SUP.8: Config Mgmt. | | - ORG.4: Training |

| - SWE.1: Sw Req. | | - SUP.9: Problem Solv. | | |

| - SWE.2: Sw Design | | - SUP.2: Verification | | |

| - SWE.3: Sw Implement| | ... | | |

| - SWE.4: Sw Integration | | |

| - SWE.5: Sw Testing | | |

+----------------------+ +-------------------------+ +-----------------------------+

(This shows the three main process groups and example processes inside each.)

2. ASPICE Capability Levels Pyramid

+-----------------------------+

| Level 5: Optimizing |

+-----------------------------+

| Level 4: Predictable |

+-----------------------------+

| Level 3: Established |

+-----------------------------+

| Level 2: Managed |

+-----------------------------+

| Level 1: Performed |

+-----------------------------+

| Level 0: Incomplete |

+-----------------------------+

(Visualizes progression from Level 0 to Level 5; most companies target Level 2 or 3.)

3. ASPICE V-Model Mapping

Requirements Design Implementation Testing

| | | |

| | | |

V V V V

+----------------+ +----------------+ +----------------+ +----------------+

| SYS.2 | | SYS.3 | | SWE.3 | | SWE.4, SWE.5, |

| System |--->| System Design |--->| Sw Implement. |-->| SWE.6 |

| Requirements | | | | | | Integration & |

| Analysis | | | | | | Testing |

+----------------+ +----------------+ +----------------+ +----------------+

(Shows flow from requirements to design, implementation, and testing, aligning with V-Model and ASPICE processes.)

4. Example: Requirements Traceability Matrix (Simplified Table)

| Requirement ID | Design Doc Section | Test Case ID | Status |

|---|---|---|---|

| SYS-REQ-001 | 3.2 | TC-001 | Covered |

| SWE-REQ-002 | 4.1 | TC-005 | Covered |

| SYS-REQ-003 | 3.4 | TC-008 | Pending |

(Traceability of requirements through design and test phases is a key ASPICE principle.)

5. ASPICE Assessment Process Flow

[ Preparation ]

|

v

[ Document Review ]

|

v

[ Interviews & Evidence Gathering ]

|

v

[ Scoring of Process Areas ]

|

v

[ Reporting & Recommendations ]

Automotive SPICE (ASPICE) Implementation Workflow

+---------------------------+

| 1. Management Buy-in |

+-----------+---------------+

|

v

+---------------------------+

| 2. Training & Awareness |

+-----------+---------------+

|

v

+---------------------------+

| 3. Gap Analysis |

+-----------+---------------+

|

v

+---------------------------+

| 4. Process Definition & |

| Documentation Update |

+-----------+---------------+

|

v

+---------------------------+

| 5. Tooling Selection & |

| Customization |

+-----------+---------------+

|

v

+---------------------------+

| 6. Pilot Project |

| (Test & Adjust Processes) |

+-----------+---------------+

|

v

+---------------------------+

| 7. Internal Audit |

+-----------+---------------+

|

v

+---------------------------+

| 8. Organization-wide |

| Rollout |

+-----------+---------------+

|

v

+---------------------------+

| 9. External Assessment |

| (by ASPICE Auditors) |

+-----------+---------------+

|

v

+---------------------------+

| 10. Continuous |

| Improvement |

+---------------------------+